High Expectations, Uncertain Benefits: Industry 4.0 and Improving Corporate Sustainability Performance

08.04.2022

Company representatives expect that digitalisation will improve the environmental sustainability of their organisations. However, actual experience paints a less positive picture: new technologies have so far largely failed to deliver anticipated improvements in resource efficiency. According to the researchers behind a new study, more political support is needed to harness the potential of Industry 4.0.

Industrial production needs to be fundamentally transformed if the UN Sustainable Development Goals are to be achieved. Two main objectives are at the forefront of this transformation: Decarbonisation and dematerialisation. Decarbonisation aims to reduce emissions harmful to the climate, and in particular CO2. Dematerialisation aims to produce goods and services with a minimum of material inputs. An international team led by IASS Research Group Leader Grischa Beier investigated the potential of Industry 4.0 to support these two goals in an online survey among company representatives in China, Brazil, and Germany. The team surveyed representatives across a range of industrial sectors and from companies of different sizes.

Experience translates into diminishing expectations

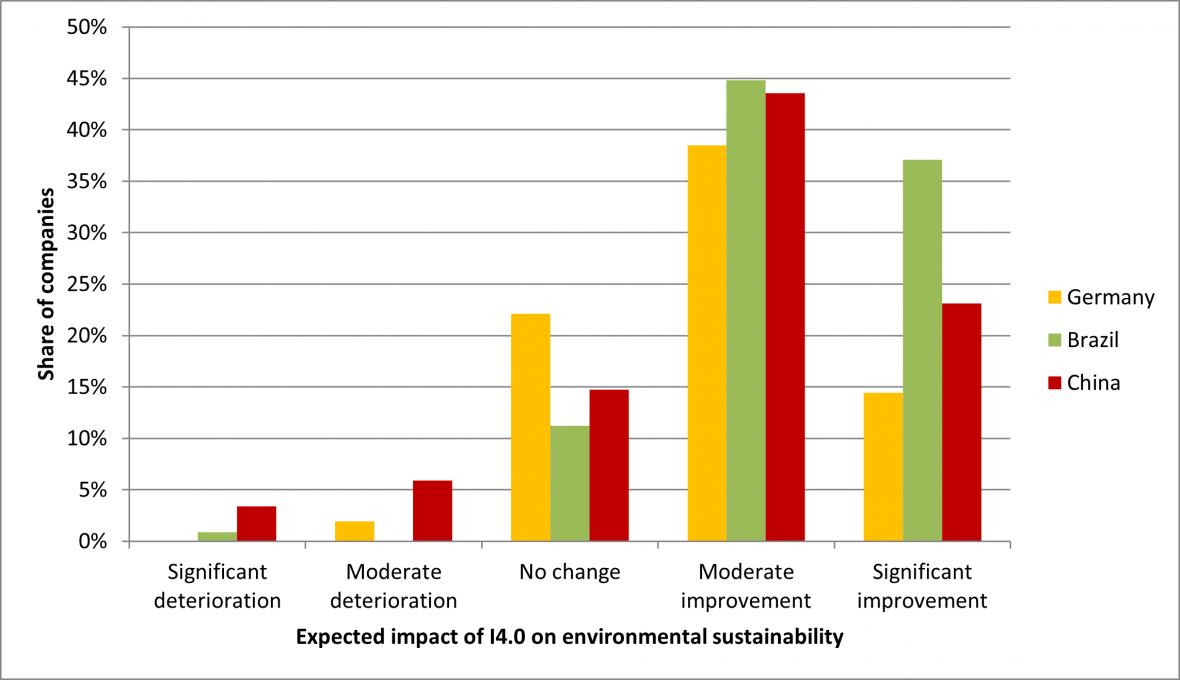

The majority of industry representatives – 53 per cent in Germany, 82 per cent in Brazil and 67 per cent in China – expect that Industry 4.0 technologies will have a positive impact on their companies’ environmental sustainability. This view was particularly pronounced among representatives of companies with more than 5,000 employees in Germany and Brazil.

The researchers observed large differences between sectors in some countries. In Brazil, expectations are particularly optimistic in the machinery and plant engineering sectors (100 per cent), and in Germany in the electronics (75 per cent) and automotive sectors (58 per cent). In China, on the other hand, there are no major differences between the sectors surveyed.

However, actual experience with Industry 4.0 technologies – in terms of resource efficiency and energy consumption – does not entirely support such optimism. “Our findings suggest that expectations are overly optimistic in companies that still have little actual experience with Industry 4.0 technologies. Companies that reported higher levels of Industry 4.0 implementation had more moderate expectations with respect to actual energy savings, for example,” explains lead author Grischa Beier. Previous studies also found little evidence to support expectations that significant savings would be achieved comprehensively.

Industry 4.0 helps companies align production with demand

On a positive note, the study finds that companies with a high level of digitalisation are well positioned to improve their sustainability performance in other areas. The higher the current Industry 4.0 level of companies, the greater their ability to align their production with the actual demand. In addition, improved digitalisation increases the willingness of companies to align production schedules with the availability of renewable electricity. According to the researchers, these so-called Demand Response schemes are an important prerequisite for the stabilisation and efficient use of future renewable energy systems.

The researchers conclude that more political support is needed to ensure that the adoption of Industry 4.0 technologies leads to improvements in environmental sustainability. "Our study shows that the implementation of the Industry 4.0 concept should be critically evaluated against the background of the UN Sustainable Development Goals: the mere digitalisation of production processes will not suffice to advance the transition towards a more sustainable economy. In order to take full advantage of the potentials of digitalisation for corporate sustainability management, it must be flanked by supporting regulations and incentives, including the establishment of binding targets for saving energy and materials,” explains Grischa Beier. Although the results paint a mixed picture, it is clear that the widespread uptake of Industry 4.0 offers opportunities for companies to improve their environmental sustainability

Beier, G., Matthess, M., Guan, T., Grudzien, D. I. d. O. P., Xue, B., Lima, E. P. d., Chen, L. (2022): Impact of Industry 4.0 on corporate environmental sustainability: Comparing practitioners’ perceptions from China, Brazil and Germany. - Sustainable production and consumption, 31, 287-300.

https://doi.org/10.1016/j.spc.2022.02.017

Contact